Corona Treatment on Blown Film Lines

AFS is reliable. Always.

Corona Treatment on Blown Film Lines.

Packaging today is a very complex composite of different materials. They can be laminated, metallised, printed and coated. The requirements of the customers for these packages and the materials are extremely high.

AFS products are the result of mature development processes. More than 30 years of experience flow daily into innovations and high quality standards.

That’s why AFS systems are among the best-selling treatment stations in the world.

Our designers also make complicated customer requests possible. Diverse plant sizes and associated options always offer a tailor-made solution.

Seven different system types cover the blown film line widths, all typical resin types and installation situations are catered for.

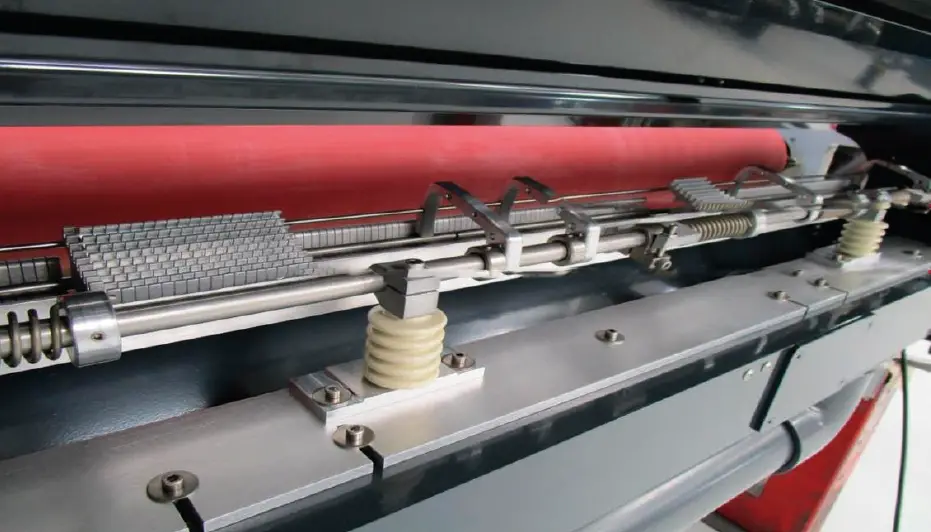

From the simple, hand-operated treater station to bus-controlled plant with pressure rollers, drives and water cooled rollers can be integrated into your production line.

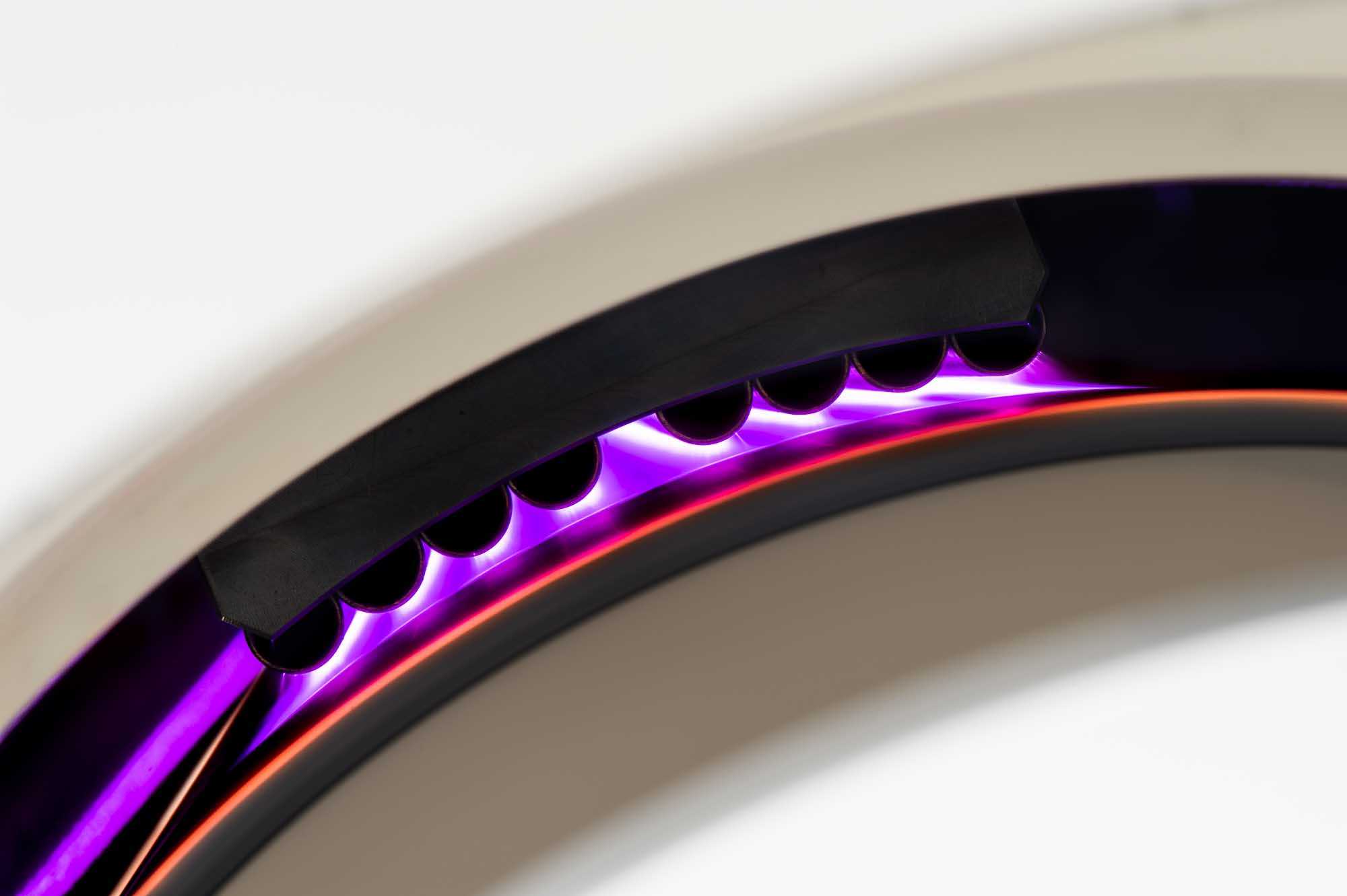

Our safety standards are subject to continuous testing. The corona treatment requires high voltage. We have encapsulated all live parts with a completely metal housing. As insulation material we only use glazed ceramics. The electromagnetic radiation remains at the lowest level due to the metallic shielding.

We will only use first class materials in our construction, a critical point for permanent corrosion resistance. With proper maintenance and care our systems are still in operation decades later.

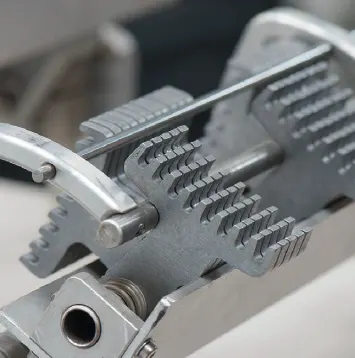

Retention Bar

For larger segmented electrodes, a spring loaded retention bar design prevents inactive segments from falling back while keeping the active segments perfectly aligned in their correct position.

Stainless steel shim rings between each electrode key. Allows for ease of movement and prevention of clogging.

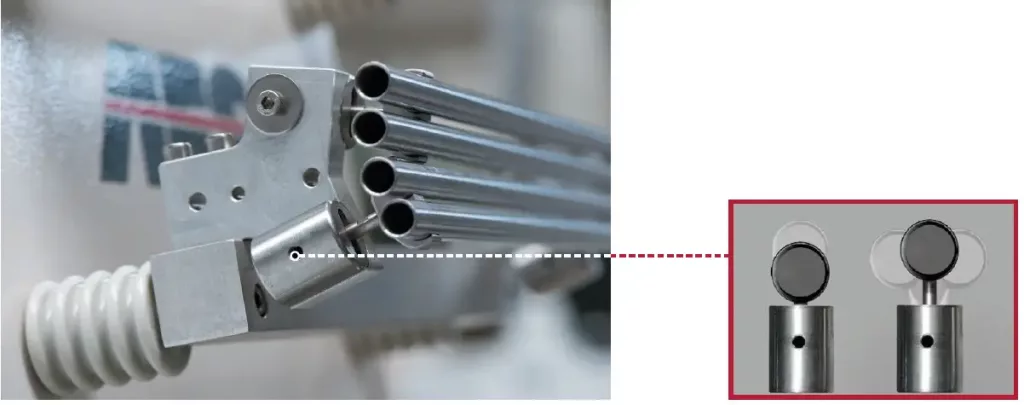

Segmented Electrodes

in three different sizes

3-, 6-, or 9-finger in aluminium or stainless steel and in various widths according to customers wishes.

3-finger

6-finger

9-finger

Continuous Electrode

If a segmented electrode is not required, then a good alternative is our stainless steel tubular electrode with “smart hinge” mounting as also used on Cast Film Lines.

AFS Generators

AFS Generatoren für höchste Porduktionssicherheit und Produktivität

Our latest generator technology combines reliability and efficiency with optimal process integration at low operating costs introducing the industry 4.0 standard by allowing for remote maintenance.

Isolated air flow cooling duct for the electronic components avoiding maintenance intensive filter cleaning at our S/SE series.

The new M-Generator series of AFS is built upon a modular approach ensuring your production reliability and sustaining your productivity. The number of modules can be tailored to every application.

- All AFS generators come with a comprehensive operator action and error message log in clear text and in multiple languages.

- Key internal parameters are monitored with an early warning system allowing for corrective actions without production loss.

- The M2 generator type allows for individual power adjustment on each electrode optimizing investment costs and space compared to two separate generators.

- State of the art design with a clear and intuitive operating interface.

- To change a module is the work of minutes and we provide a step by step instruction in our documentation. No special tools or skill-set needed.

- For challenging climatic conditions we offer matching supplementary cooling units with proven track record.

System Highlights

- Safe and easy operator access for setting and cleaning.

- All remote interfaces available, Profi-Bus, Can-Bus, Profi-Net, Ethernet, etc.

- CE conformity.

- No external high voltage cables. Transformers are connected directly to the electrodes.

- No plastic insulation or shielding.

- FS only use ceramic insulators and our designs allow for a suffi cient air gap between the electrode and side covers. Some competitors use plastic shielding for a more compact, cheaper design, but over time, these materials absorb salts and moisture leading to frequent fl ashovers and increased downtime for cleaning.

- Fully enclosed metal housings with a low EMC compared to other designs with plastic shielding.

Typische Optionen

Corona-Pro

A built–in fully automatic system which at low power level, will pulse the generator output to ensure a homogenous corona discharge across the entire width thereby avoiding the risk of patchy treatment.

Damp-Start

In areas of high humidity, the problem of condensation forming during any down-time can result in production delays while the station is dried out manually to avoid stoppages due to flash-overs.

The damp start feature gets you back into production faster by burning off this condensation in a very short time enabling production to recommence.

Look Back

In addition to the standard error message and operator action log in every AFS generator, the look back feature will store all parameters on an internal SD Card with recall and trending features available via the generator display. Additional extensions to the system are a USB download portal or a LAN interface to copy data files for offline storage and viewing.

AFS Catalysers

Corona treatment generates ozone of which the KAT-System eliminates approximately 99%. AFS can supply the right catalyser for every station.

Technical Details

| Attribute | Details |

|---|---|

| Application Details | Blown Film Extrusion |

| Working Width | 600 - 3500 mm as standard |

| System Version | Single-sided or double-sided or four-sided |

| Electrodes depending on plant typep |

- 3-, 6- or 9-finger segmente - electrodes - Stainless steel tubular electrodes - Ceramic electrodes |

| Working Line Speed | up to 300 m/min, higher speed possible |

| Treater Roller depending on plant type | - Silicon dielectric (sleeve or coating) - Ceramic coating - Corrosion-proof coating - Aluminium |

| Generators | 1 - 144 kW, higher output power on request |

| Technical Highlights | - The best electrode mounting on the market (AFS patent) - External adjustable spray gap - Customer design-specific corona stations - Robust, reliable and compact design for extremely easy cleaning and maintenance - High efficiency of the corona generators benefits the user in capital and operating cost |

| Options | - Pressure roller - Drives for treater rollers - Water cooling - Banana guide roller - Spreader roll |

Request now

Let our AFS service team assist you

AFS at a glance

- AFS systems are designed for smooth continuous operation.

- AFS only uses high-quality components from selected suppliers in all its systems.

- AFS products are recognized industry standard.

- AFS offers a full two-year warranty.

- AFS is the preferred partner of OEMs, global players and quality-conscious end customers.

We are looking forward to your inquiry

More contact options

Telephone: +49 (8294) 80494-0

Fax: +49 (8294) 80494-45

Mail: info@afs.biz

Von-Holzapfel-Straße 10

86497 Horgau