Perforation

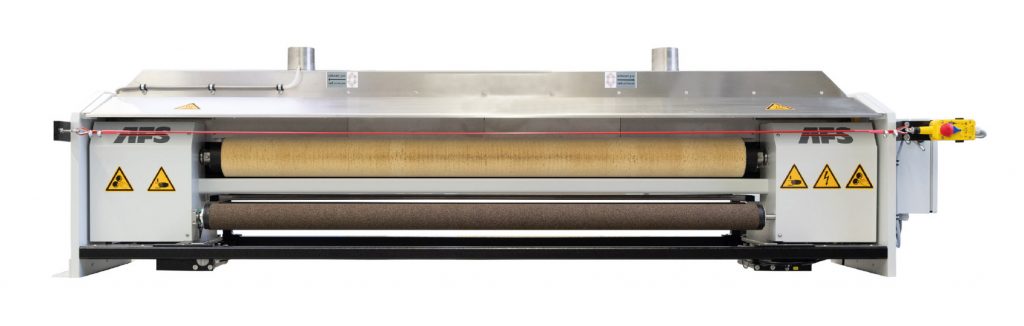

The perforating machine PM5 & PM6

AFS is reliable. Always.

The perforating machine PM5 & PM6.

The PM-Series is the AFS solution for hot or cold needle perforation of plastomers etc. The production of air-permeable food and vegetable packaging can be integrated into any continuous flat film process.

The advantates of AFS perforating machines

- Easy operation due to intuitive touch screen display.

- Emergency release springs during machine standstill reduce the risk of fi re.

- Precise interruption of the perforating process in transverse direction, thanks to intermittent operation (with PM6).

- Effective multi-zone needle roller heating.

For an effective foil perforation

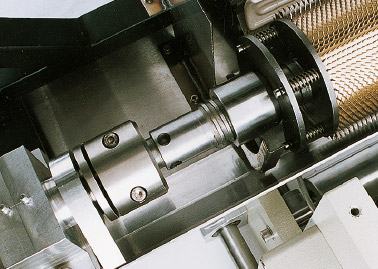

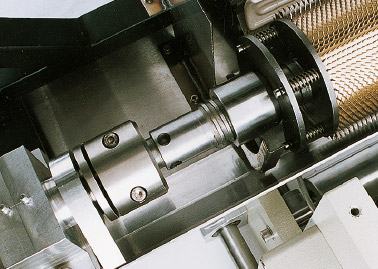

The PM series essentially consists of two parts: the needle roller part (heating part) and the foil guide part with brush and deflection rollers.

To insert the film, the film guide part is moved away from the needle roller. The film can be easily inserted. The interlocking of needle and brush roller, i.e. the penetration depth of the needles into the film, can be infinitely adjusted. The plunge depth defines the hole diameter.

The horizontal roll displacement does not change the wrapping length of the film when the machine opens

Economical in energy consumption

Although the perforation process takes place at temperatures of up to 350°C, the energy consumption of the system is pleasingly low. Separate heating and extraction chambers ensure that only the air surrounding the melting area is extracted and the energy loss due to waste heat is thus reduced to a minimum.

High safety standard

f the web speed falls below an adjustable minimum, the film is automatically removed from the perforation area in order to avoid unwanted melting effects.After reaching an adjustable web speed, the film is automatically returned to the perforation area.

After switching off the system, the hot needle roller rotates until a minimum temperature is reached. This avoids the risk of a stationary roller bending during cooling.

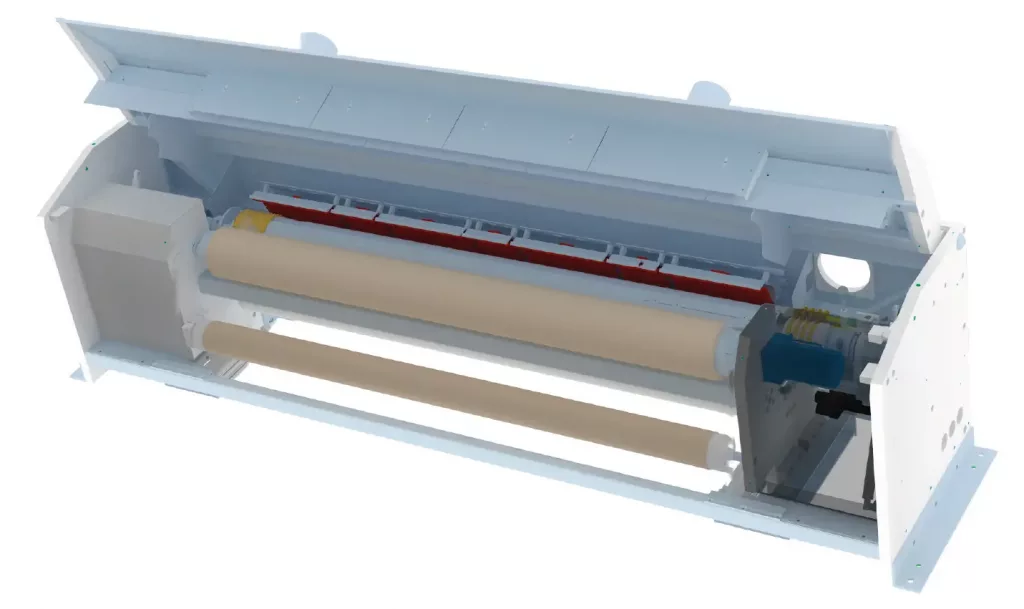

Lid with extraction hood and extraction monitor

Perforating roller

Spiral brush roller

movable by pneumatic cylinder Stroke = 100 mm

External heating by infrared radiator

Drive

Needle roller with toothed belt tensioner

Eccentric drive for intermit-tent operation (PM6 only)

Needle segments

Deflection roller

Internal heating of needle rollers

Convenient operation

The graphic touch screen and the one-button control contribute considerably to simple operation. The process parameters temperature and piercing depth can be clearly displayed on the display and changed using the multifunction button or directly by tapping on the display.

More

Feautres

Hole patterns can be varied as required with short set-up times

The simple removal and installation of the needle roller as well as the modular needle segment system enable a quick change to other hole pattern patterns or multiple use through any needle segment combination.

With the electronically controlled piercing depth control, the hole diameter can also be infi nitely adjusted.

High production speeds with perfect perforation quality

With the combination of external and internal heating, temperature determination within the roll and high-precision temperature control, the PM series creates the prerequisites for perfect perforation results even at high web speeds.

Intermittent operation (PM6)

Film manufacturers sometimes require unperforated spaces for adhesive surfaces, for example.

Our model PM6 offers a millimetre accurate and lightning fast interruption of the perforating process even at high web speeds.

The unperforated zones can be configured quickly and conveniently via the menu on the control cabinet or via a factory bus.

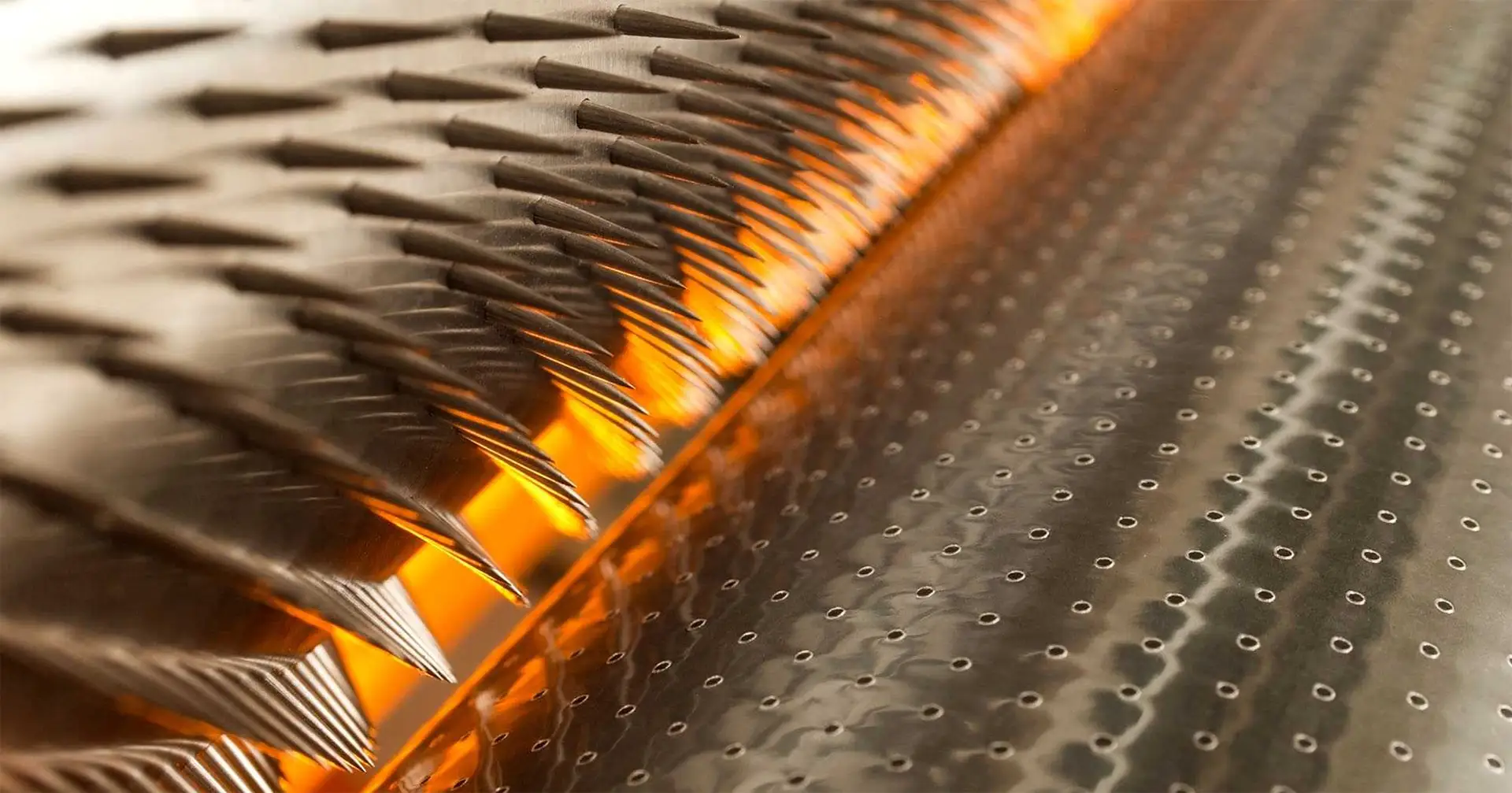

HOT NEEDLE/WARM NEEDLE PERFORATION

Many thermoplastic fi lms such as PP have to be hot perforated to maintain tear strength. An electrically heated and synchronously driven needle roller in combination with a heat-resistant counter roller guarantee absolutely round holes with cleanly welded edges.

This process meets the highest aesthetic demands while at the same time off ering high tear resistance.

More sensitive PE fi lms can be treated with warm needle perforation. Instead of hole melting, the fi lm is merely thermoformed here.

DRYPOINT PERFORATION (PM10)

In this process, conical needles pierce the web (e.g. paper, thin metal foils, PE foils). Instead of a brush roller, a grooved counter roller is used. The grooves of the counter roller fi t exactly to the needle pattern. The needles create funnel-shaped holes. This results in increased water permeability, e.g. for paper. Since no material is removed during this process, the holes can partially close again when pressure is applied to the web.

Application Examples

Hygiene and medicine

Hygiene and medicine are large areas of application for perforation: Perforated plasters allow air to penetrate the areas to be protected and still protect against contaminating substances. The healing process progresses faster. In the case of roll-fed plasters, the perforation also serves to facilitate tearing. A special type of perforation enables a so-called "one-way street eff ect" of liquids. This means that liquids can be transported away at the place of their origin and collected in storage media. This eff ect can only be achieved to a limited extent with needles. The perforation of non-woven materials for hygienic applications requires relatively large holes and high web speeds. A process specially developed by AFS meets these requirements to a special degree.

Filling with bulk materials

If powdery materials are packed, the air must be able to escape quickly from the bag. The perforation serves this purpose. At the same time, the hole size must be exactly adapted to the product to be fi lled. If bulk material or powdery goods are to be fi lled into plastic or paper containers, perforation ensures that the displaced air can escape more quickly. The maximum fi lling speed increases. Example: Cement, earth, milk powder etc.

Perforation of coffee filters

The perforation increases the liquid throughput and controls it in a targeted manner. Hole density and diameter control the brewing time. The result is coff ee or tea of varying strength.

In construction and agriculture

Perforated fi lms have proven to be the best way to keep moisture out while still ensuring air circulation. This application serves as a protective layer between thermal insulation and interior fi nishing, especially in the renovation of old buildings. Example: Roof liner

Packaging of food

Perforated plastic fi lm is often used for packaging fresh products such as bakery products, vegetables and fl owers. The perforation of the fi lm allows the moisture of the product to escape from the packaging, which prevents the fi lm from fogging up without impairing the freshness retention eff ect. Flowers and vegetables stay fresh, baked goods crispy.

Technical Details

| Attribute | Details |

|---|---|

| Perforation width PM5 | 600 - 2000 mm (others on request) |

| Perforation width PM6 | 600 – 1300 mm |

| Perforation speed | 200 m/min mechanically possible, material-dependent |

| Dimensions (perofration)) | - Height: 745 mm + 290 mm (for opening)

+ 50 mm (optional adjustment unit) - Width: Perforation width + 1140 mm - Depth: 560 mm + 200 mm (for opening) |

| Dimensions (control cabinet) | - Height: 1600 mm + 200 mm base - Width: 600 mm - Depth: 500 mm |

| Heating capacity | - Heater - approx. 8500 W/m - Roller - approx. 8500 W/m |

| Needle segments | Customer specific - typical widths 50 / 100 mm - offset or linear needle patterd |

| Hole diameter | - optimal results at Ø 0,3 – 1,0 mm, - max. Ø 2,8 mm |

Request now

Let our AFS service team assist you

AFS at a glance

- AFS systems are designed for smooth continuous operation.

- AFS only uses high-quality components from selected suppliers in all its systems.

- AFS products are recognized industry standard.

- AFS offers a full two-year warranty.

- AFS is the preferred partner of OEMs, global players and quality-conscious end customers.

We are looking forward to your inquiry

More contact options

Telephone: +49 (8294) 80494-0

Fax: +49 (8294) 80494-45

Mail: info@afs.biz

Von-Holzapfel-Straße 10

86497 Horgau