Printing, Lamination and Coating

You can rely on AFS. Always.

Printing, Lamination and Coating

Packaging today is a very complex composite of different materials. They can be laminated, metallised, printed and coated. The requirements of the customers for these packages and the materials are extremely high.

They are designed to provide durability and different barrier properties and of course stable attractive colours. The trend to reduce the level of solvents in adhesives and paints has to also be taken into account. All this places high demands on the production process.

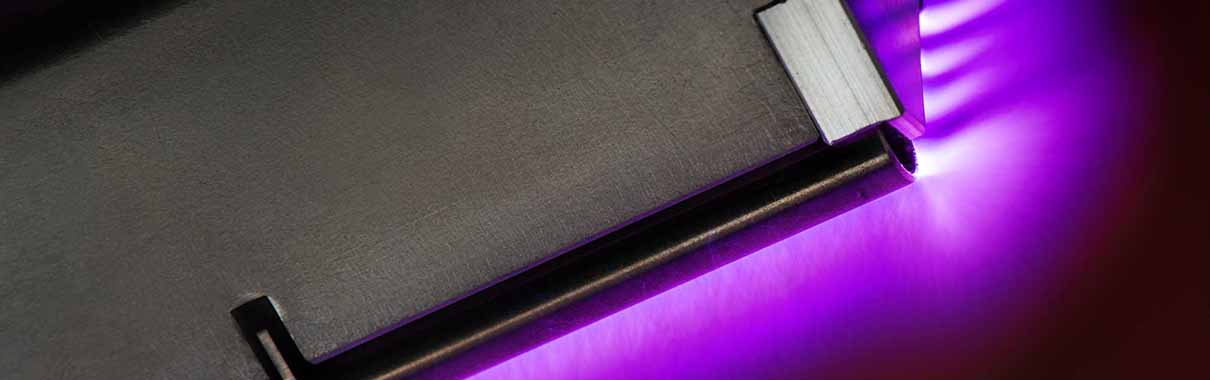

AFS investments are a key part of this process providing adhesion to plastic, paper or metal surfaces as part of the packaging integrity so that the contents stay fresh.

The required surface tension for printing, lamination and coating will reduce from the level reached by corona treatment during the extrusion process over a period of time in transportation or storage. This effect, caused by, for example, waxes and lubricants in the material requires that prior to the subsequent process Corona treatment is again necessary. By this so-called refreshment the surface tension

of a substrate is increased, or the surface energy level reached in the first treatment is restored , so improving the wettability and the adhesion to the substrate surface.

Multiple system configurations

AFS offers a variety of system configurations, which can be based on the particular application, as standard or as a customised system easily integrated into existing and new production lines. End users as well

as OEM customers benefit permanently from the great flexiblity, know-how and the innovations of AFS and enjoy technical perfection with simple operation..

More Features

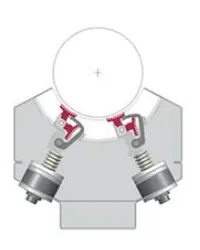

Ceramic electrodes of AFS

The ceramic electrodes of AFS have revolutionized the market. Its patented suspension makes them particularly robust and resistant to fractures which occur only very rarely. The pivoting holders allow for movement in all directions.

Spray gap

The spray gap can be set accurately and reproduced from the outside.

System Example

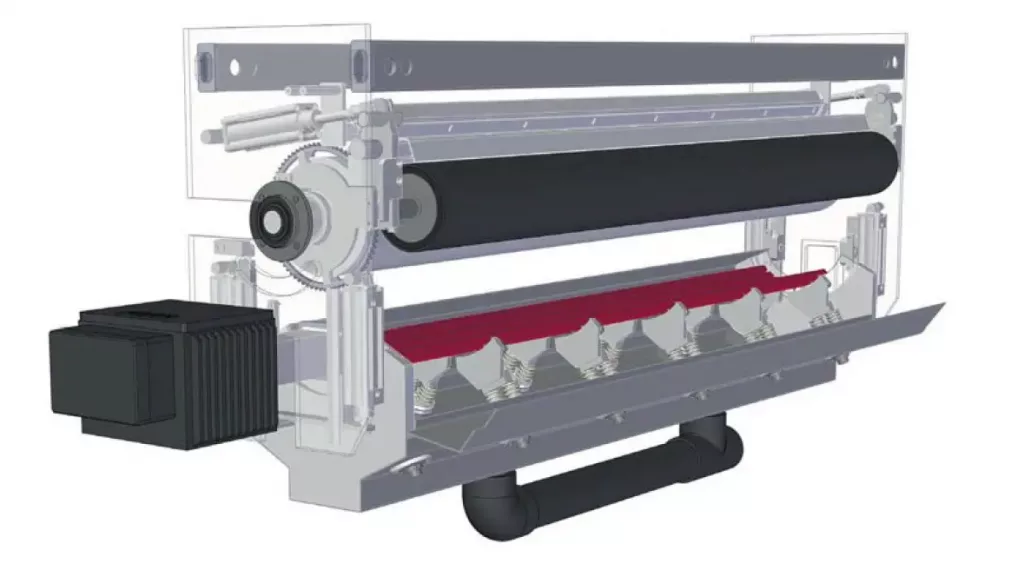

Allround-System AVE-250E

The AVE-250E is an all-rounder suitable for applications in printing, lamination and coating.

System configuration example: The AVE-250E

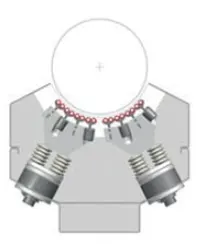

Configuration A

Electrodes: 9-finger Segmented Electrode or 2 x 9-finger Segmented Electrode

Treater Rollers: coated with silicon or ceramic

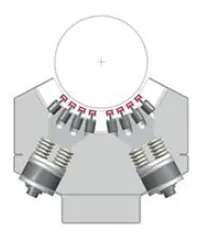

Configuration B

Electrodes: 16 High Output Electrodes in Stainless Steel

Treater Rollers: coated with silicon or ceramic

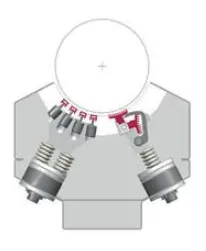

Configuration C

Electrodes: 8 High Output Electrodes in Ceramic

Treater Rollers: Coated with corrosion protection or ceramic

(rarely with silicon) or bare aluminum

Configuration D

Electrodes: 9-finger Segmented Elec-trode and 4 High Output Electrodes in Ceramic

Treater Rollers: coated with silicon or ceramic

Technical details

| Attribute | Details |

|---|---|

| Application Details | Printing, Laminating, Coating |

| Working Width | 800- 4000 mm |

| System Version | Single-Sided or Double-Sided |

| Electrodes depending on plant type |

- max. 2 x 9-finger Segmented electrode - max. 32 High Output Electrodes in Stainless Steel - max. 2 x 10 High Output Electrodes in Stainless Steel with special cooling cassette - max. 22 High Output Electrodes in Ceramic - Combination of Segmented and Ceramic Electodes possible |

| Treater Roller epending on plant type |

Silicon Coated, Ceramic Coated, Aluminium blank or with Corrosion-proof Coating |

| Working line speed | Up to 1000 m/min |

| Generators | 1 – 96 kW, higher output on request |

| Technical Highlights | - The best Electrode mounting on the market (AFS Patent) - External Spray Gap adjustment - Customer design-specific Corona Stations - Robust, reliable and compact design for extremely easy cleaning and maintenance - High efficiency of the corona generators benefits the user in capital and operating cost |

Request now

Let our AFS service team assist you

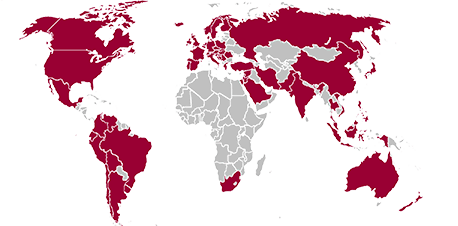

AFS at a glance

- AFS systems are designed for smooth continuous operation.

- AFS only uses high-quality components from selected suppliers in all its systems.

- AFS products are recognized industry standard.

- AFS offers a full two-year warranty.

- AFS is the preferred partner of OEMs, global players and quality-conscious end customers.

We are looking forward to your inquiry

More contact options

Telephone: +49 (8294) 80494-0

Fax: +49 (8294) 80494-45

Mail: info@afs.biz

Von-Holzapfel-Straße 10

86497 Horgau