Chinaplas 2024: vom 23.4.24 – 26.4.24

AFS wird wie immer Teil des Deutschen Pavillons sein und freut sich darauf, sowohl neue Kunden, die an unserer Technologie interessiert sind, als auch bestehende Kunden zu produktiven Gesprächen zu treffen.

Drupa 2024: 28.5. – 7.6.

Besuchen Sie uns in Halle 14, Stand C33 Die Vorbehandlung im Converting ist eine Domäne von AFS. Patentierte Elektrodenaufhängungen, eigens entwickelte Keramikelektroden für die Vorbehandlung von leitenden Materialien und Papier und gut abgestimmte Antriebe sorgen für beste Ergebnisse. Jahrzehnte lange Erfahrung in der Zusammenarbeit mit Herstellern von Druck,- Kaschier und Beschichtungsanlagen haben zu einer optimalen […]

K 2022 vom 19. – 26. Oktober 2022

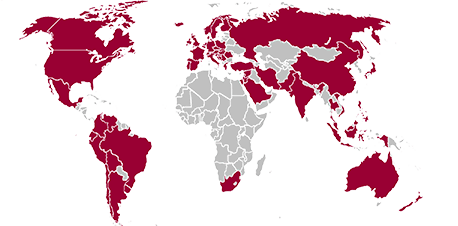

Besuchen Sie uns: Halle A6 , Stand 471 Der zentrale Treffpunkt für die internationale Kunststoff-Industrie 2022 sind wir selbstverständlich wieder auf der weltweit führenden Messe für Kunstoffe aller Art vertreten.. Die Besucher der K-Messe kommen aus unterschiedlichsten Branchen, wie zum Beispiel Verpackung, Kunststoffe, Druck, Papier, Maschinenbau, Textil-/ Vliesstoffgewerbe, Chemie, Automobil, Nahrungsmittel, Elektronik, Arzneimittel/ Gesundheit/ Medizin, […]

Segmentwechselstation für Perforationsanlagen

Um Rüstzeiten zwischen einzelnen Produktionen auf ein Höchstmaß zu optimieren, kann mit unserer neu entwickelten Segmentwechselstation jetzt schon während des laufenden Auftrages eine Nadelwalze für die nächste Produktion mit Nadelsegmenten bestückt werden.

Industrie 4.0 und Fernwartung in Krisenzeiten bei AFS

In unkontrollierbaren Situationen wie wir Sie aktuell mit der anhaltenden COVID-19 Problematik erleben ist es wichtig, vorbereitet zu sein. Unsere AFS-Generatoren mit TFT-Display sind bereits seit Jahren mit Fernwartungsschnittstellen ausgestattet, die im Bedarfsfall einen schnellen und einfachen Online-Support durch unser AFS-Serviceteam ermöglichen. Bei den aktuell anhaltenden Reiseverboten ist das oftmals die einzige Möglichkeit bei einem […]

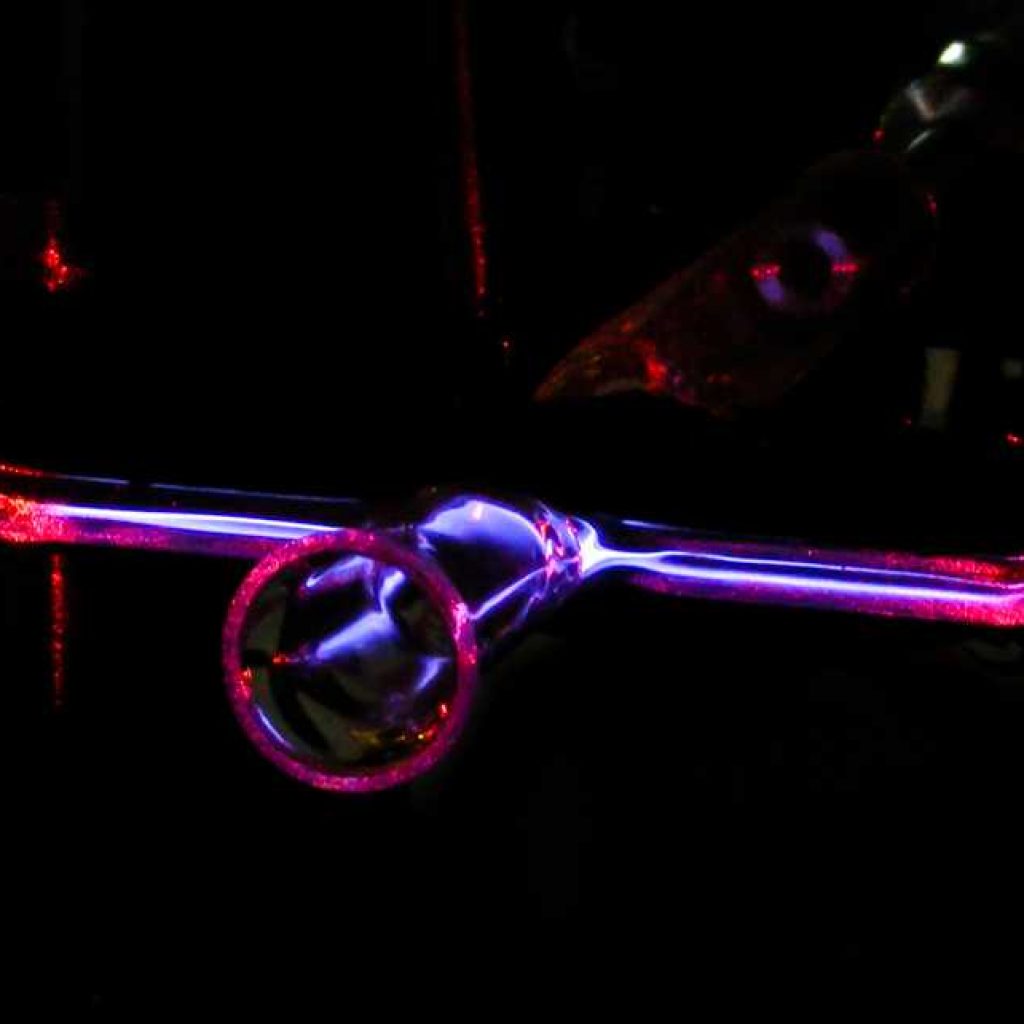

Start von PIONEER

PIONEER ist ein Europäisches Projekt im Rahmen des H2020-Programms mit dem Ziel, eine neue Generation von Experten für das multidisziplinäre Forschungsfeld von Plasma und Katalyse im Kontext der CO2 Umwandlung auszubilden. 15 Doktoranden (genannt ESR) werden innerhalb eines Konsortiums von 15 renommierten europäischen Forschungseinrichtungen und sechs industriellen Partnern zusammenarbeiten. Das Ziel ist, neue Systeme in […]