Products

Plasma – Corona – Perforation

Learn more about our product portfolio

The scope of application for our equipment: Improvement of adhesion by means of plasma and corona treatment as well as the production of breathable film by needle perforation, hot or cold. Moreover, we support our customers with tailor-made equipment for their specific plasma process.

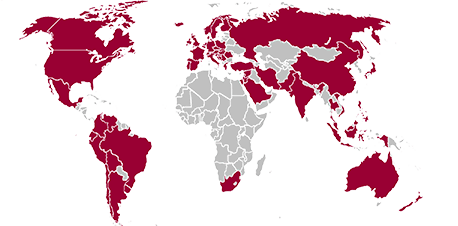

Our ambition: Premium systems for uninterrupted operation with world-wide service.

Product overview

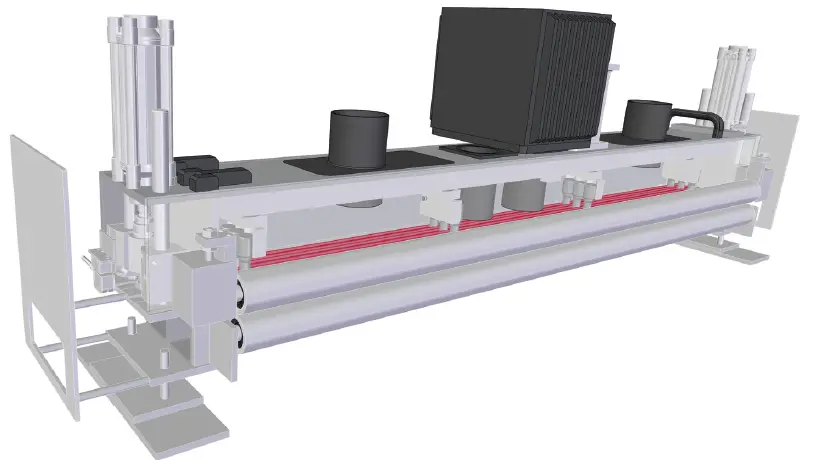

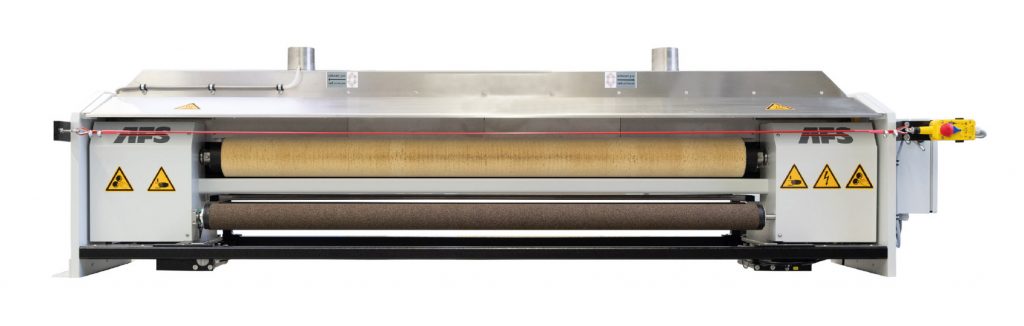

Corona Treatment on Blown Film Lines

Packaging today is a very complex composite of different materials. They can be laminated, metallised, printed and coated. The requirements of the customers for these packages and the materials are extremely high.

Surface treatment with wet chemical primers belong in the past. With AFS ALDYNE™ the same results can be achieved, saving costs, effort and time. Environmentally unfriendly wet chemical waste, and energy intensive drying processes can be precluded.

They stand for continual innovation, high flexibility and robust designs. They are built to offer the

highest efficiency, user-friendliness and reliability. All generators operate with the same innovative

technology, AFS has developed and improved over many years. They operate with the highest

efficiency at the resonant frequency, ensuring the longest possible operating life and the greatest

output energy yield from the mains supply.

PlasmaJet ®

The Plasmajet® produces a plasma without a vacuum. The plasma, generated by high voltage in combination with any process gas, is blown out of the unit, and is potential-free. It is used for surface modification.

Printing, Lamination and Coating

Packaging today is a very complex com-posite of differnt materials. They can be laminated, metallised, printed and coated. The requirements of the customers for these packages and the materials are extremely high.

Corona treatment of metal sheets

Where sheet metal (painted and unpaint-ed) requires lamination or coating, adhe-sion is an important issue.

Corona pre-treatment for cast film

In recent years, cast film lines have been built faster and wider. Widths over five meters and production speeds around 400 m / min are not unusual. Polypropylene films are often produced on cast film lines, which can only be pretreated with a high energy input and very often only to a surface energy of 44 to 46 mN / m. The PP foils are usually only treated on one side, either the front or the back.

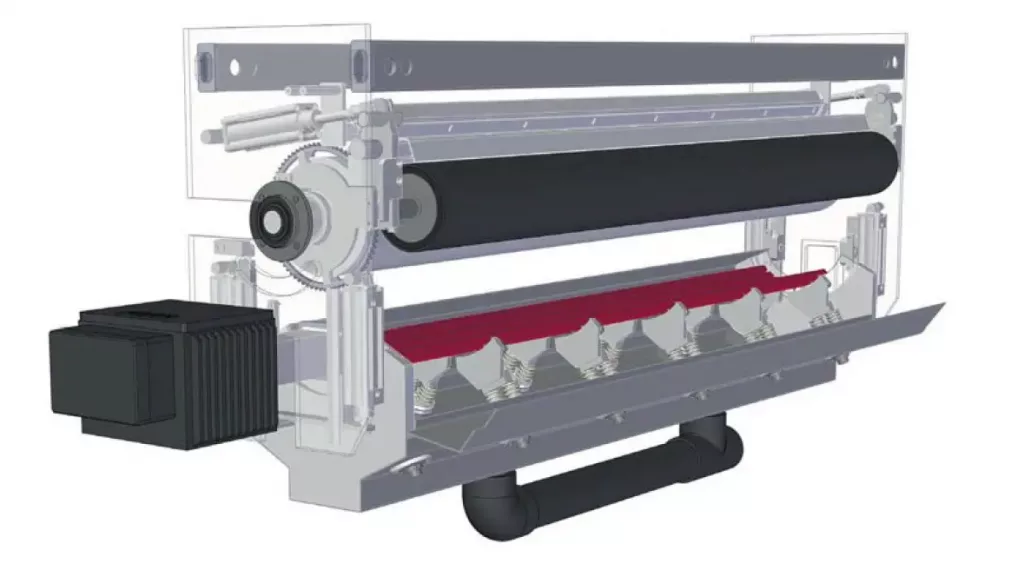

The PM-Series is the AFS solution for hot or cold needle perforation of plastomers etc. The production of air-permeable food and vegetable packaging can be integrated into any continuous flat film process.

The AV-R is a flexible corona station for internal and external surface pre-treatment of polymer pipes. The extruded polymer pipe is used as dielectric between the inner and outer electrode.

For rapid measurement of the surface tension of polyethylene or polypropylene films.

Request now

Let our AFS service team assist you

AFS at a glance

- AFS systems are designed for smooth continuous operation.

- AFS only uses high-quality components from selected suppliers in all its systems.

- AFS products are recognized industry standard.

- AFS offers a full two-year warranty.

- AFS is the preferred partner of OEMs, global players and quality-conscious end customers.

We are looking forward to your inquiry

More contact options

Telephone: +49 (8294) 80494-0

Fax: +49 (8294) 80494-45

Mail: info@afs.biz

Von-Holzapfel-Straße 10

86497 Horgau