Corona pre-treatment for cast film

You can rely on AFS. Always.

Corona pre-treatment for cast film

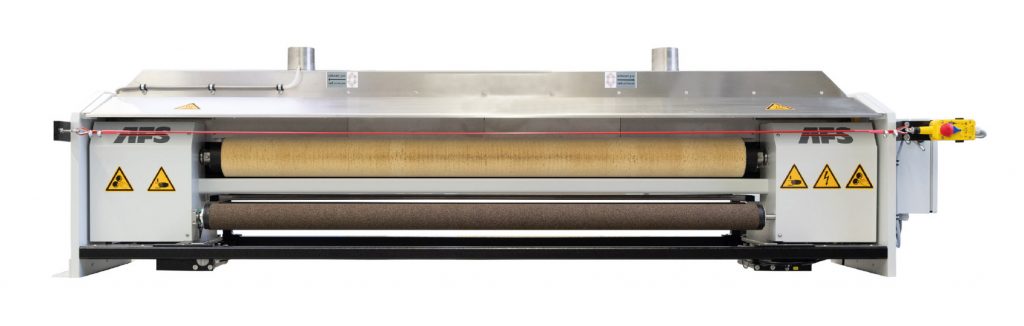

In recent years, cast film lines have been built faster and wider. Widths over five meters and production speeds around 400 m / min are not unusual. Polypropylene films are often produced on cast film lines, which can only be pretreated with a high energy input and very often only to a surface energy of 44 to 46 mN / m. The PP foils are usually only treated on one side, either the front or the back. Pretreatment of the other side (back side effect) is almost always undesirable and can lead to problems in the subsequent processes. This places special demands on the corona pretreatment system.

The Generators

The high energy input for high speeds and wider widths requires high generator outputs. Our module generators (see generator) with a maximum output of up to 144 kW effortlessly cover the required performance spectrum. With a single generator with contactor circuit, you can select the side to be pretreated either directly on the generator or remotely via the BUS connection. If both sides are to be pretreated, the double generators (M2) from AFS are recommended for total flexibility.

The Pre-treatment station

In order to place the high generator outputs on the film without damaging the films, some of which are heat-sensitive, many good individual solutions are required in the pretreatment station. Potential issues are for example. wrinkles, which can lead to a reverse side effect and impair the pretreatment result. Optimal ventilation of the electrode chamber prevents excessive heating of the electrodes and thus also of the foil. In addition, water-cooled pre-treatment rollers support the process of adequate heat dissipation.

The design of our tubular electrodes has changed over 30 years of experience with cast film lines and are the optimal choice. The roller coatings used have also been optimized in terms of dielectric properties, efficiency and robustness in a process that has taken years. Our pressure rollers ensure that there is no reverse side effect caused by an air cushion between the pre-treatment roller and the film with a precisely calculated camber for perfect contact between the film and the roller.

The Transformers

The transformers are compactly mounted on one side of the corona station to ensure the high-voltage connection to the electrode is as short as possible. Minimum electrical losses in the high-voltage circuit and reduction of any wear parts enables long-term trouble-free operation.

Safety

High voltage, a fast-moving web and many moving parts in the system increase the risk of injury to the operating personnel. The dangers are identified in our detailed risk analyses and eliminated by means of covers or other measures, such as an op-tionally available complete enclosure of the system. Even when the humidity is high, our generous calculations regarding the spacing between electrodes to our purely metallic electrode housing ensure a safe and error-free production.

Exhaust fans

Our exhaust fans are explicitly ozone-resistant and dimensioned to ensure compliance with the occupational exposure limit values around our facility. With an optional silencer, the noise emissions can be reduced considerably.

Corona-Station

High clarity operating panel with multi-function rotary control dial and TFT touch screen.

Precise spray gap setting using AFS electrode adjustment units (calibrated from 0.9 to 2.3 mm).

High voltage transformer: all high-voltage cables are laid inside the Corona station.

Precise profiling of the pressure / nip rollers guarantee optimally distributed pressure for back side-free pre-treatment.

Carefully designed electrode cassette concepts with targeted air flow ensure optimal pre-treatment results.

Maximum operator protection possible through various protective devices.

AFS Generators

AFS generators ensure production reliability and productivity

Our latest generator technology combines reliability and efficiency with optimal process integration at low operating costs.

The standard remote maintenance exceeds the industry standard 4.0.

The new M-Generator series from AFS is based on a modular approach that ensures your production reliability and productivity. The number of modules depends on the desired maximum power and can be enlarged for additional redundancy.

- Modern design with a clear and intuitive user interface.

- All AFS generators have a comprehensive operator action and error message log in plain text and in several languages.

- The internal process parameters are monitored with an "early warning system", which enables corrective measures without production down-time.

- The M2 generator type enables individual performance adjustment on each electrode, which optimizes investment costs and space requirements compared to two separate generator0

- All available remote control interfaces such as Profi-Bus, Can-Bus, Profi-Net, Ethernet, etc.

- Changing a module is easy and takes just a few minutes. Step-by-step instructions are included in our documentation. No special tools or skills are required.

- For demanding climatic conditions we offer suitable additional cooling units, which have proven themselves over time.

Typical options

Corona-Pro

With very low Corona outputs, the generator can automatically activate the CoronaPro mode. This enables a homogeneous power distribution over the entire electrode width and thus a uniform pre-treatment result.

Wet start

The wet start function electrically dries the station and prevents stoppages due to flashovers. The system will be ready for use again shortly, as the resulting condensation evaporates very quickly.

Lookback

The LookBack function shows all process parameters graphically as a diagram on the generator display. A USB and an Ethernet interface are available for further data evaluation.

AFS Highlights

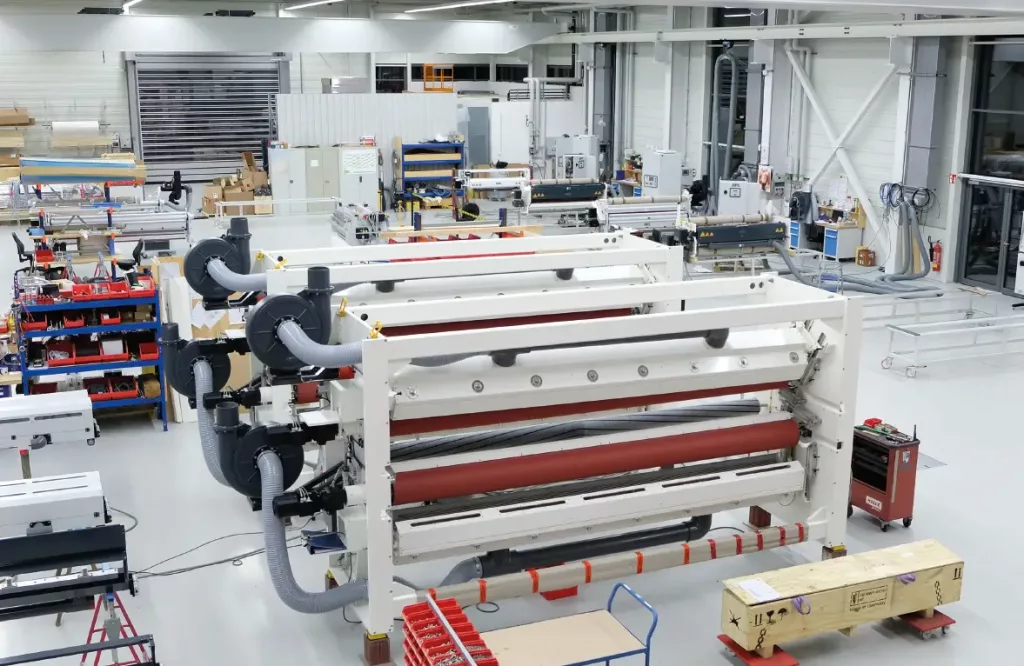

High quality standard

At our site, we produce in modern assembly halls to ensure the usual high quality standard. The energy requirements of the assembly hall are covered in an environmentally friendly and sustainable manner with inhouse solar power.

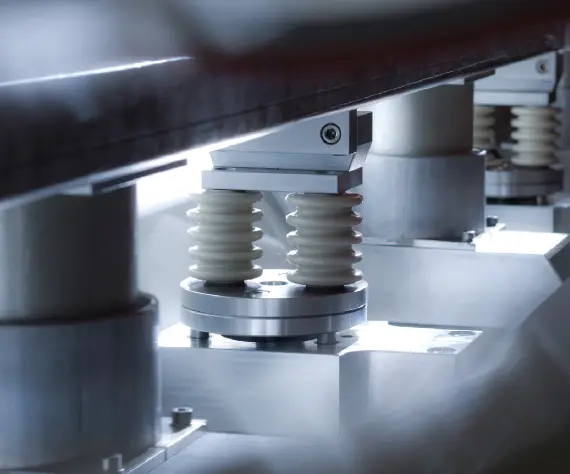

Ceramic insulators

AFS only uses ceramic insulators. Our design allows sufficient clearance between the electrode and the side covers. This is a big advantage over plastic enclosures, as over time they absorb salts and moisture, which can lead to frequent flashover failures and excessive downtime for cleaning. In addition, cleaning itself is simplified by better accessibility.

Requirements for cleanrooms

On request, we can even manufacture completely in stainless steel. Complex requirements for cleanrooms can thus be met.

Technical Data

| Attribute | Details |

|---|---|

| Application | Cast film treatment |

| Typical working width range | 2000 - 5000 mm as standard |

| System types | - Stainless steel tubular electrodes - Ceramic electrodes |

| Dielectric on the pre-treatment roller | - Silicone - Ceramic |

| Web speed | Up to 400 m/min, Higher speeds are possible |

| Generator power range | 1 - 144 kW, Higher output power on request |

| Options | - Pressure roller - Drive for treatment roller - Water cooling - Stretcher roller |

| Technical highlights | - The best electrode holders on the market (AFS-Patent) - External spray gap adjustment - Specific station design according customers requirements - Robust, reliable and compact design for extremely easy cleaning and maintenance - The high efficiency of the corona generators benefits the user in terms of investment and operating costs |

Request now

Let our AFS service team assist you

AFS at a glance

- AFS systems are designed for smooth continuous operation.

- AFS only uses high-quality components from selected suppliers in all its systems.

- AFS products are recognized industry standard.

- AFS offers a full two-year warranty.

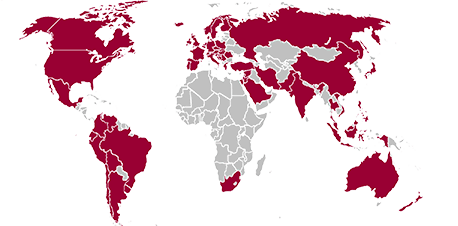

- AFS is the preferred partner of OEMs, global players and quality-conscious end customers.

We are looking forward to your inquiry

More contact options

Telephone: +49 (8294) 80494-0

Fax: +49 (8294) 80494-45

Mail: info@afs.biz

Von-Holzapfel-Straße 10

86497 Horgau