ALDYNE™

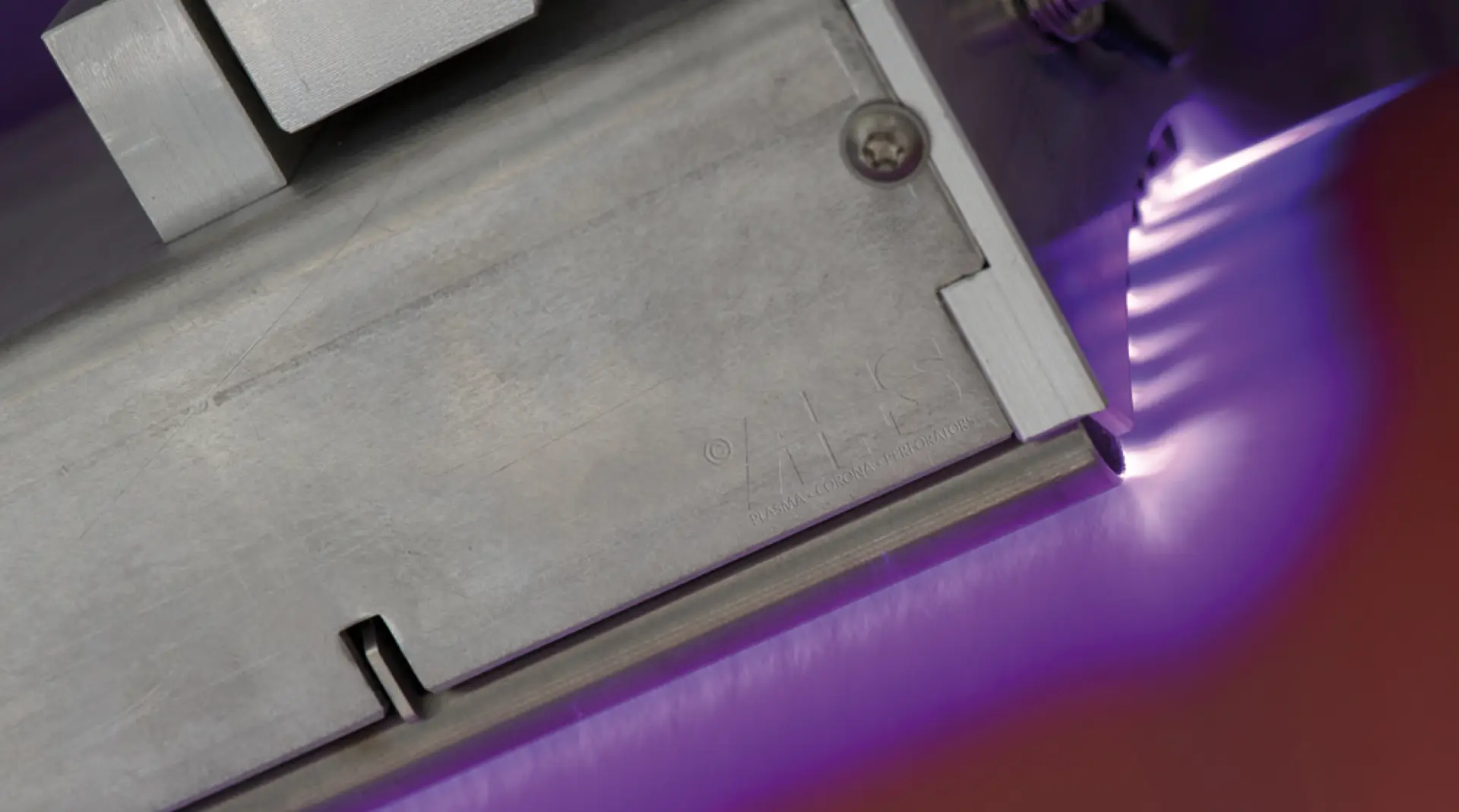

Plasma Surface Modification

Plasma Surface Modification

AFS is reliable. Always.

The perfect replacement for primer.

Surface treatment with wet chemical primers belong in the past. With AFS ALDYNE™ the same results

can be achieved, saving costs, effort and time. Environmentally unfriendly wet chemical waste, and energy intensive drying processes can be precluded.

ALDYNE™is prepared for new market developments and is constantly being developed further by our R&D department. Adhesion can be achieved with ALDYNE™ on sensitive materials without damaging the surface. This surface modification in the nanometre range leaves optical characteristics of products unchanged.

Product Features

Plasma treatment in process gas atmospheres

With precisely controlled process gas mixtures. Direct injection of the gas mixture through the electrodes ensures homogeneous gas distribution in the plasma discharge. In additionto the over pressure of the process gas, the patented labyrinth system at the web inlet and outlet provides sealing of the process chamber against ambient air.

Safety

Safety first. The SOFTAL system deactivates the plasma discharge and gas supply should a system error occur.

Independent cooling

of the treatment roller and electrodes for high power ensure no adverse thermal effect on the substrate. The special coolant used for our patented plasma electrodes is provided from a separate cooling unit.

Technical features

- Direct adhesion by modification of the uppermost 10 nm of the product surface.

- High process speed achieved with patented inlet labyrinth and optimised gas supply directly in the plasma discharge.

- Best effect using electrodes compatible for individual applications: Metal electrodes for non-conductive materials and high process speeds. Temperature controlled ceramic electrodes for conductive and thermally sensitive materials.

- Compact construction.

- Electropneumatic opening of the electrode housing for cleaning, setting up, and servicing.

- Adjusters on the top side of the station for setting of the electrode air gap and gas.

Technical data

| Attribute | Details |

|---|---|

| Electrode types (alternativ) | Ceramic or Metal |

| Carrier gas | Nitrogen |

| Number of process gases | max. 2 |

| Treatment roller | Diameter 400 mm, CERAL™-P coated, water cooled.t |

| Process speed | max. 400 m / min (higher on request) |

Request now

Let our AFS service team assist you

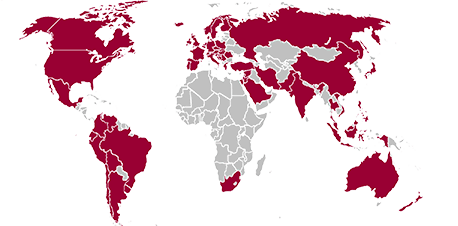

AFS at a glance

- AFS systems are designed for smooth continuous operation.

- AFS only uses high-quality components from selected suppliers in all its systems.

- AFS products are recognized industry standard.

- AFS offers a full two-year warranty.

- AFS is the preferred partner of OEMs, global players and quality-conscious end customers.

We are looking forward to your inquiry

More contact options

Telephone: +49 (8294) 80494-0

Fax: +49 (8294) 80494-45

Mail: info@afs.biz

Von-Holzapfel-Straße 10

86497 Horgau