PlasmaJet ®

Innovative surface treatment and modification

AFS is reliable. Always.

The PlasmaJet ®

An innovative process for the treatment and modification of surfaces.

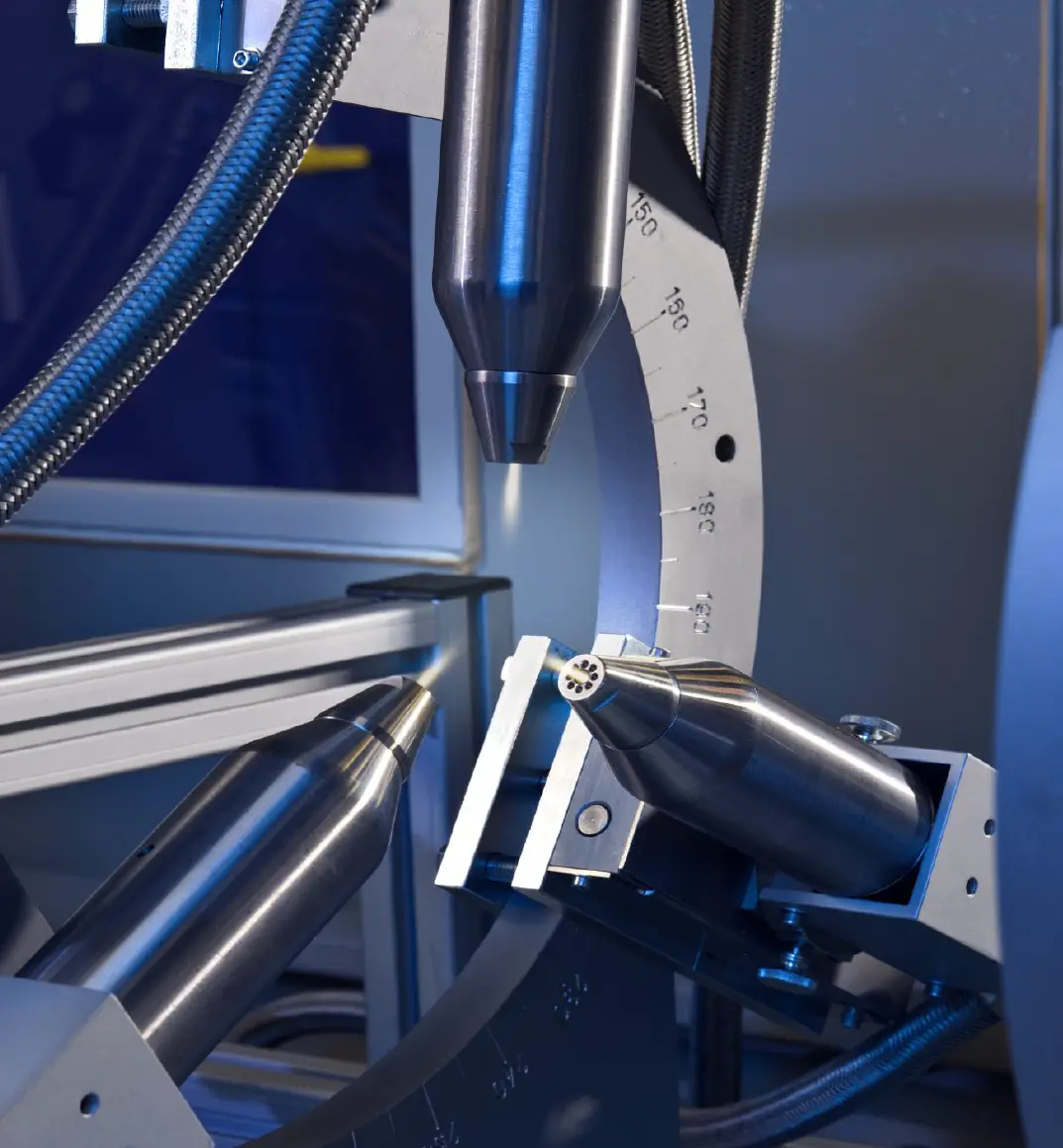

The Plasmajet® (registered AFS trademark) produces a plasma without a vacuum. The plasma, generated by high voltage in combination with any process gas, is blown out of the unit, and is potential-free. It is used for surface modification.

The system comprises of a plasma reactor with nozzle, a high-voltage generator with transformer and high-voltage rectifier.

Advantages of this process

- Atmospheric pressure process, no vacuum technology required

- Extremely low operating costs (energy consumption per nozzle approx. 500 W)

- Very safe and clean process compared to flame treatment systems

- Potential-free plasma beam, hence conductive materials can be treated without any problems

- Good operability of the plasma nozzles, both individually and combined as a group for complex applications

- Separate function monitoring of each plasma nozzle

What is Plasma?

Plasma is an electrically conductive gas consisting of positive and negative ions, electrons, excited and neutral atoms and molecules. In physics, it is often referred to as the 4th state of matter. Plasma is not stable and requires a permanent supply of energy.

PlasmaJet® function

A PlasmaJet® system always consists of a high-voltage generator and a plasma nozzle. Inside the plasma nozzle, the plasma is generated by a high-voltage discharge between two electrodes. The process gas flows around the electrodes, where it becomes plasma and due to its flow exits through a nozzle to the outside. This is referred as remote plasma and the low-cost process gas is air.

Excellent treatment results can already be achieved with this. By selecting the right outlet nozzle, it is also possible to treat workpiece geometries which are difficult to access. The low weight of the plasma nozzle and the flexible gas and energy supply make the PlasmaJet® universally applicable.

Generators

AFS Generators: Unprecedented power output

The generators, especially developed for PlasmaJet® applications, enable unprecedented power output. For surface treatment, 500 W per nozzle is sufficient. For welding and cleaning, a maximum of 1000 W per nozzle power is required.

G10P:

Generator in 1/2 19″ housing for one nozzle with max. 1000 W effective power output

Generator in 1/2 19″ housing for two nozzles with a max. effective power of 1200 W

G05P:

Generator for one nozzle with max. 500 W effective power output for multi-nozzle applications (exclusively for control cabinet installation)

Features of all generators

- Extensive plaintext self-diagnosis system in various languages

- Power control

- Setpoint limitation

- Power measurement and display in Watts

- All connections pluggable

- Voltages, currents, temperature and power setpoint displayable during operation

- Process gas monitoring

- Max. ambient temperature is 40°C

Features G10/G12P

- Potential-free output for operational readiness

- Temperature monitoring with advance warning, display in °C or °F

- Switching output for process gas

- RS232 interface for the connection of a remote control etc.

- Error memory with realtime-clock and operating hours counter

Features

Features AFS PlasmaJet ®

- Fast pulsing of the plasma beam for synchronous short interruption in the direction of operation

- Quiet treatment process due to the special generator technology

- New generator concept for maximum energy utilization

- Processor control for constant and reproducible treatment results

- Bus-capable (CAN-bus, Profi-bus, MOD-bus, etc.)

- Allow mounting on a robot arm, e.g. to treat complex contours or three-dimensional bodies

- The process is also perfectly suited for welding running plastic webs, even in contours

Applications

- Surface activation to increase wettability (e.g. car body parts and headlight components in automotive sector, circuit boards, glass and PC pan-els, window profiles, etc.)

- Improve the durability and reliability of adhesive bonds

- Treatment of silicone, PTFE and EPDM profiles before flocking or application of bonded coatings

- Electrical neutralisation of static charges

- Cleaning

- Dust removal

- Creation of functional layers on various substrates

- Single thread treatment in the production of fabrics

- Longitudinal and contour welding of plastic films

- Bonding PE / PP films with non-woven

Request now

Let our AFS service team assist you

AFS at a glance

- AFS systems are designed for smooth continuous operation.

- AFS only uses high-quality components from selected suppliers in all its systems.

- AFS products are recognized industry standard.

- AFS offers a full two-year warranty.

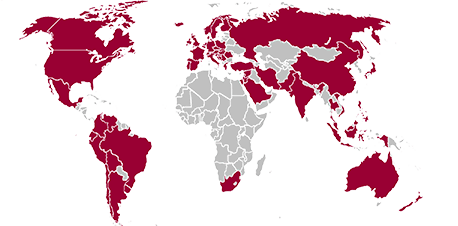

- AFS is the preferred partner of OEMs, global players and quality-conscious end customers.

We are looking forward to your inquiry

More contact options

Telephone: +49 (8294) 80494-0

Fax: +49 (8294) 80494-45

Mail: info@afs.biz

Von-Holzapfel-Straße 10

86497 Horgau