Steel Pretreatment

Corona treatment of metal sheets

You can rely on AFS. Always.

Corona treatment of metal sheets

Where sheet metal (painted and unpainted) requires lamination or coating, adhesion is an important issue.

Notably, in the production of sandwich panels, the sheet is treated with corona for better adhesion of the foam. Also when using foams with a higher flash point.

In addition, bright sheet metal can be cleaned with corona pre-treatment.

What is special about the treatment of sheet metal?

In contrast to plastic films, treatment rollers are generally not used in the corona treatment of metal sheet, as the grounded metal sheet is the counter electrode.

This special unit has been developed in cooperation with one of the world’s largest sandwich panel manufacturers, and several are in long term production with proven reliability.

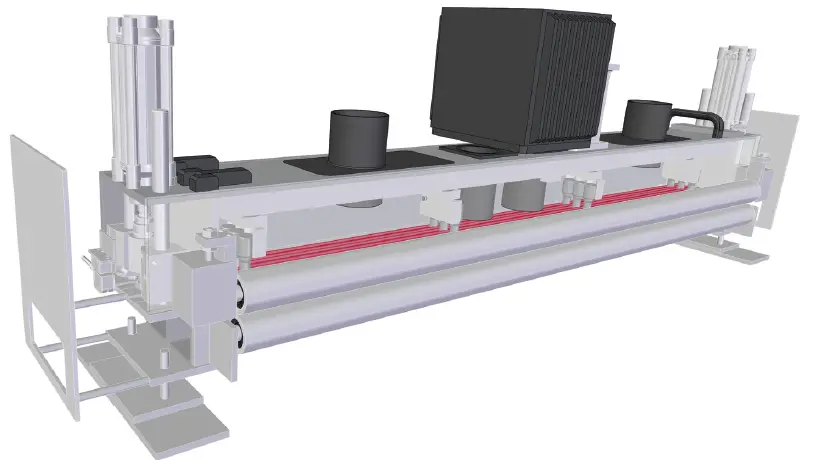

How has the treatment station been optimized?

oller pairs at the inlet and outlet of the station precisely define the distance between the metal sheet and the ceramic electrodes, preventing them from being damaged by warps in the metal sheet.

The unit is fitted with special ceramic electrodes with stainless steel cores for durability in the hard mechanical process. Additional optional protection of the ceramic electrodes can be realized using a fast open system. A splice can detected via a signal from the line or by an interrupted laser beam which opens the station and closes it again after the splice has passed.

The optimized extraction can prevent conductive particles from the sheet from causing flashovers on the electrodes which may lead to damage. The electrode holders have additional shields to protect against this occurring.

Ease of maintenance and accessibility.

To facilitate easy cleaning and simple exchange of the electrodes, the station is easily opened for access to the ceramic electrodes. Inspection plates on the electrode chamber also allow fast cleaning in between the individual electrodes.

Pneumatic cylinders open the system (also for a splice to pass through)

Hinged top for easy access during maintenance.

High-voltage transformer.

High voltage connections are routed inside the station

Extraction.

Optimized extraction helps to prevent metallic particle formation on the electrodes. Efficient Ozone removal.

Easy feed through of the metal sheet when the station is open.

Grounded roller pairs at the inlet and outlet of the system define an exact discharge gap independent of the material thickness. They also provide even pressure to guide the sheet safely through the station.

Closed housing with ceramic electrodes and protective cover.

AFS Generator

The generator output is a high frequency AC voltage, approximately 500V (15-50 KHz). The power output is regulated. A range of settings and menu items are available.

High stability against power fluctuations

Where mains power supply fluctuations occur, the generators can compensate for light to medium fluctuations where many generators have problems maintaining constant performance.

Air conditioner

Investigations have proved that at high ambient temperatures, the life of sensitive electrical components is reduced. A wide range of climate solutions from passive cooling to super-charged cooling units are offered to combat this.

The diagnostics and operator memory

The operator memory stores the last 50 changes on the generator with time stamps making the operating process transparent. For example: When the corona started or performance adjustments made? The diagnostic memory displays in clear text the last 100 messages enabling a consistent quality assurance in production.

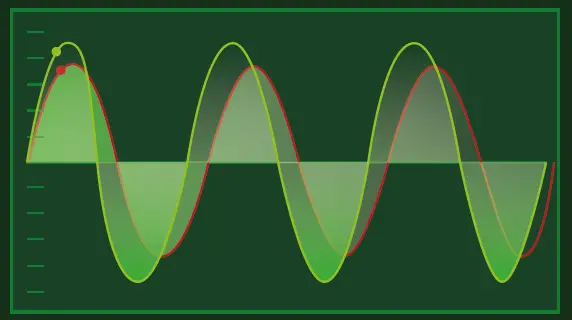

Operation in the resonant frequency

Generators operate at resonant frequency. This means that the inverter circuit is constantly checked and regulated such that no reactive currents are generated and the systems operate at maximum efficiency. When changes in conditions occur, the frequency is automatically adjusted until the phase shift returns to zero degrees.

Air conditioner

Investigations have proved that at high ambient temperatures, the life of sensitive electrical components is reduced. A wide range of climate solutions from passive cooling to supercharged cooling units are offered to combat this.

Ceramic Electrodes

Sophisticated electrode design

The ceramic electrodes are the result of decades of experience in the field of corona treatment.

For example, the one-sided corona metal sheet treatment station is equipped with four ceramic electrodes (see picture on the left). These are connected to the output of the high voltage transformer. The high voltage is approximately 10-12 kVrms at 30 kHz.

Conductive webs such as metal sheet can only be corona treated with a ceramic electrode design.

The protective housing completely encloses the electrode. This provides efficient extraction of the ozone and reduces radio interference as far as possible.

System Highlights

- Safe and easy operator access for setting and cleaning.

- All remote interfaces available, Profi-Bus, Can-Bus, Profi-Net, Ethernet, etc.

- CE conformity.

- Transformers are connected directly to the electrodes.

- No plastic insulation or shielding.

- AFS only use ceramic insulators. Our designs allow for a sufficient air gap between the electrode and side covers. Some competitors use plastic shielding for a more compact, cheaper design. Over time, these materials absorb salts and moisture leading to frequent flashovers and increased downtime for cleaning.

- Fully enclosed metal housings with a low EMC radiation.

Technical Details

| Attribute | Details |

|---|---|

| Application | Metal sheet treatment (e.g. sandwich panels) |

| Working width | 600 - 2000 mm |

| System Versions | Single sided (treatment top side or bottom side) |

| Electrode | max. 7 High Output Ceramic Electrodes |

| Line Speeds | Up to 100m/min |

| Gernator | 1 – 14 kW depending on treat width |

| Technical Highlights | - Customer specific designed Corona-Station - Stable and safe path through grounded guide rollers - High ceramic electrode protection - Robust, reliable and compact design for easy cleaning and maintenance - High efficiency corona generators results in low operating costs and improved ROI Generators withstand strong power fluctuations - Fast Open (splice) on web thickening (option) |

Request now

Let our AFS service team assist you

AFS at a glance

- AFS systems are designed for smooth continuous operation.

- AFS only uses high-quality components from selected suppliers in all its systems.

- AFS products are recognized industry standard.

- AFS offers a full two-year warranty.

- AFS is the preferred partner of OEMs, global players and quality-conscious end customers.

We are looking forward to your inquiry

More contact options

Telephone: +49 (8294) 80494-0

Fax: +49 (8294) 80494-45

Mail: info@afs.biz

Von-Holzapfel-Straße 10

86497 Horgau